The sprockets are first molded or forged and subsequently processed, giving them a special heat treatment. If steel does not contain sufficient quantities of carbon, then it becomes brittle during the hardening process. If only the surface is hardened, then the sprocket or segment will wear very fast over time.

Item No :

SprocketOrder(MOQ) :

1 PCSPayment :

T/T, L/C, D/P, Western UnionProduct Origin :

ChinaColor :

Yellow Black or CustomizedLead Time :

7-15 daysWeight :

37.8KgPacking :

Wooden Pallet PackingExcavator Sprocket SY215 Drive wheel Undercarriage Parts Segmen

Introducing the Superior Excavator Sprocket:

Unleash the true power of your excavator's performance with our top-of-the-line Excavator Sprocket. Designed to withstand the toughest terrains and extreme workloads, this essential machine component is the key to unlocking efficiency and maximizing productivity.

Crafted from premium-grade materials, our Excavator Sprockets exhibit exceptional durability and longevity, ensuring reliable performance throughout your rigorous operations. Engineered to withstand the harshest environments, these sprockets are the epitome of strength, precision, and dependability.

Product Features

| Name | Excavator Undercarriage Sprocket |

| Material | 35MnB |

| Finish | Smooth |

| Colors | Black |

| Technique | Forging / casting |

| Surface Hardness | HRC52-58,deepth:8mm-12mm |

| Warranty time | 1 year |

| Certification | ISO9001 |

| Delivery Time | Within 5-17 days after contract established |

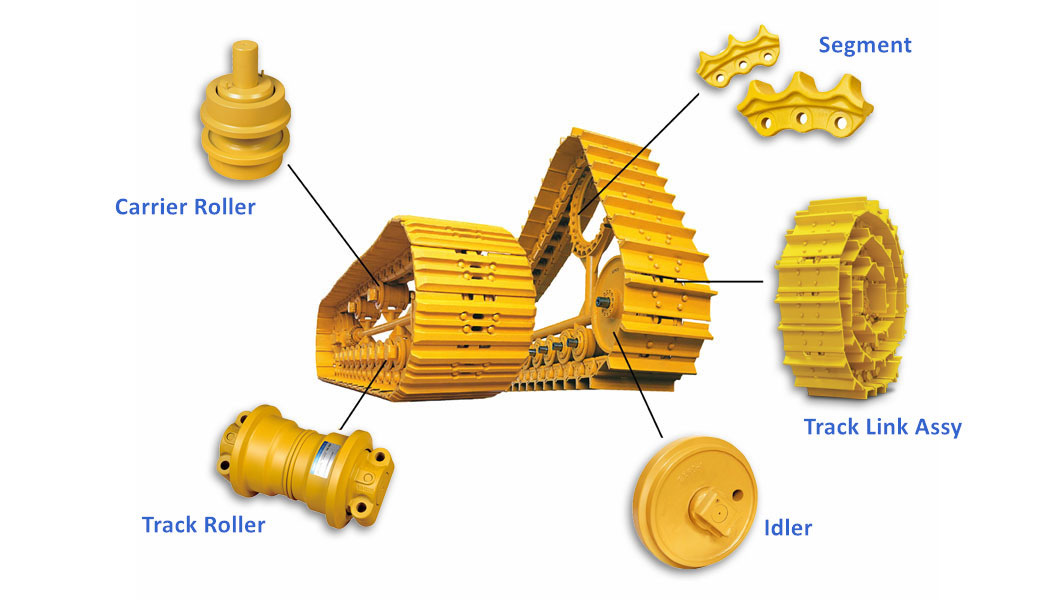

What is a Sprocket?

The sprockets are first molded or forged and subsequently processed, giving them a special heat treatment. If steel does not contain sufficient quantities of carbon, then it becomes brittle during the hardening process. If only the surface is hardened, then the sprocket or segment will wear very fast over time.

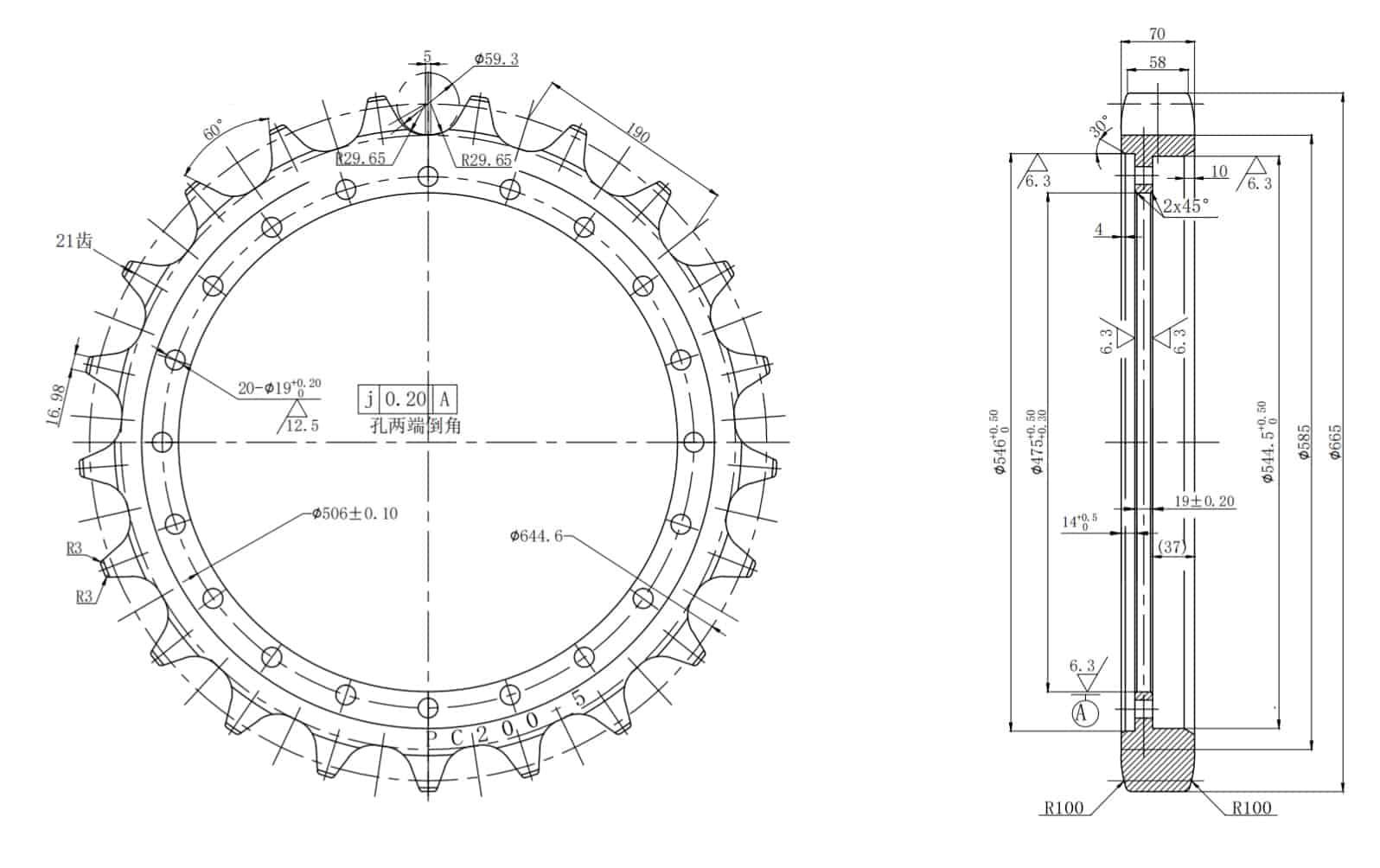

Structure and Main Dimensions of Installation

Main Parameters

The models listed below are for reference only; we cannot display all available models here. We can provide additional products based on your specific requirements. Please feel free to send us your inquiry.

| Brand | Model | Main Dimensions of Installation | ||||||

| A | B | D | S | M | N | G | ||

| CATERPILLAR | E120B | 130 | 108 | 142 | 42 | |||

| E200B | 140 | 120 | 164 | 47 | ||||

| E225 | 200 | 172 | 172 | 47.7 | ||||

| E235 | 215 | 187.5 | 188 | 47.7 | ||||

| E320 | 140 | 120 | 164 | 47 | ||||

| E325 | 190 | 160 | 194 | 66 | ||||

| E330 | 190 | 160 | 194 | 66 | ||||

PC120-6 PC130 PC130-7 PC200 PC200-1 PC200-3 PC200-5 PC200-6 PC200-7

PC200-8 PC210-6 PC220-1 PC220-3 PC220-6 PC220-7 PC220-8 PC270-7 PC202B

PC20-7 PC30 PC30-3 PC30-5 PC30-6 PC40-7 PC45 PC45-2 PC55

PC220LC-6 PC220LC-8 PC240 PC300 PC300-3 PC300-5 PC300-6 PC300-7 PC300-7K

PC300LC-7 PC350-6/7 PC400 PC400-3 PC400-5 PC400-6 PC400LC-7 PC450-6 PC450-7

PC600 PC650 PC750 PC800 PC1100 PC1250 PC2000

Excavator Track Roller Manufacturing Processes

Different types of bottom rollers

Bottom rollers for excavators have a thick axle for bearing the machine’s weight These bottom rollers have a smaller running surface diameter, because the machines do not need to do much mobile work.

Bottom rollers for mini excavators have the same characteristics as the bottom rollers of larger excavators. However, these bottom rollers have more types of mountings in the undercarriage, depending on the type and the tracks used.

Packing Size :

| Selling Units | Single Item |

| Single package size | 37 x 19.5 x 19.5 cm |

| Single gross weight | 37.800 kg |

About about us :Quanzhou Karries Machinery Manufacture Co.Ltd, is a professional manufacturer of undercariage parts, which used for excavators bulldozers and loaders.

About about us :Quanzhou Karries Machinery Manufacture Co.Ltd, is a professional manufacturer of undercariage parts, which used for excavators bulldozers and loaders.

Our main products are track rollers ,front idlers, sprocket, carrier rollers, bucket bush , tooth pin, link bushing ,track bolt , swearing bearing ,track adiuster. These parts are used for brands like komatsu, caterpillar ,hitachi, kato, sumitomo,kobelco, daewoo, hyundai,volvo,yanmar yuchai ,SWE etc. The heat treatment of our products adopts the latest German machine to strictly control and confirm the quality of the products after processing. Our company promise make our customer can rest assured.

Purchase advanced producing and inspect machines ,produce strictly according to the standards of national and industry ,we make our effort to execute the management model of modern enterprise.we have passed the SGS:ISO9001:2008 certificate,we have won the great reputation in market under the high grad service and productions , sales network has spread all over the domestic and oversea markets.

We always take the customer's needs first, improve product quality after-sales service more professional attitude to serve our customers, we pursue the long-term ist, do our professional things, make us more professional, for the company's future we have confidence, look forward to cooperation with you.

LATEST KEWS AND DEALS DIRECILY TO YOUR INBOX

Talk wth our support

+86-15805989981

Copyright @ 2025 Quanzhou Kaiyusi Machinery Co., Ltd.. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy